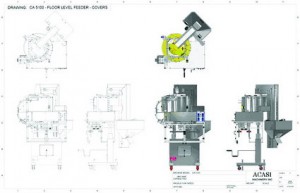

We offer the CA5100 model capping machine, which can be a great choice when it comes to tall caps. The need of maintenance is reduced due to its heavy duty design. The small footprint as it possesses is perfect for congested spaces. We also offer a floor level feeder.

Automatic Capping Machine (CA5100)

Automatic Capping Machine (CA5100)

Tightener Features:

- The caps can be fully adjusted with diameters from 8 mm to 110 mm.

- Containers can be fully adjusted with heights from 1 inch to 14 inch.

- The C frame is formed of welded heavy duty 304 stainless steel welded.

- Top and bottom belt plates are made of stainless steel.

- The shafts ranging from ¼ to 2.5 inches are made of stainless steel.

- There are 6 capping discs whose bottom screws can be easily changed over.

- Capping belt movements allow transmission of direct gear motor.

- Chain power transmission is used for powering chain caps

- There is a DC gear motor for controlling the speed of gripper belts independently.

- For independent speed of capping discs, a DC motor is in use.

- The capping discs are adjusted by frontal knobs of stainless steel and with lock nut hand wheel.

- Central 7000 mechanical jack is used to adjust capper height.

- There are a wide range of containers and these require no extra parts.

Features of Cap Transfer:

- Each and every contact parts are made of stainless steel.

- Can be fully adjusted for caps having diameters ranging from 8 mm to 110 mm.

- Can be fully adjusted for caps having diameters ranging from 5 mm to 52 mm.

- Allows adjustment of height and diameter.

- The space between upper C and cap shoe allows slotted or guided transfer in 4 ways.

Centrifugal type cap feeder features:

- Made of stainless steel.

- Feeding disc having 32 inch diameter with ramp assembly.

- Photoelectric sensor used for rejecting caps.

- Photoelectric sensor controls cap by demand

- For enabling easy tool adjustment, there is a standard 4 piece slotted cross

- There exists easy changeover for caps having diameters ranging from 10mm to 90mm.

- There exists easy changeover for caps having heights ranging from 0.125 to 2.5 inches.

- Independent height adjustment not required as the sorter is mounted on machine.

- There is a regulator for filter pressure.

- Air hoses have flow controls.

- Cap hoppers have vibration system that can be adjusted.

- Powered by 1/3 Hp DC gear motor.

- Potentiometer controls speed.

Features of Cap hopper:

- Vibrator is provided with an independent control which is mounted on cap hopper.

- Limit switch with low friction is provided for sensing cap level on centrifugal cap feeder.

- Includes stainless steel deposit having a volume of 3 cubic feet.

Electric and pneumatic requirements:

- 110 Volts, 60Hz, 15 Amps.

- 5 CFM @ 80 p.s.i.

Please Call for Price

Item available in stock!